The MC306 dome training simulator is a cutting-edge tool for immersive valve leak training, offering a safe environment to practice complex skills without real-world risks. Advanced technology replicates intricate valve systems and enables trainees to simulate various leak conditions, fostering proficiency in leak detection and repair. This game-changing simulator enhances problem-solving abilities, reduces training costs, and prepares professionals for on-site challenges, ultimately improving safety standards.

“Unleash your team’s valve leak detection skills with the revolutionary MC306 Dome Training Simulator—a game-changer in industrial safety. This cutting-edge technology offers a vibrant, immersive training experience, replicating real-world scenarios. In this comprehensive guide, we explore the MC306 hardware and its capabilities, unraveling the benefits of hands-on practice. From setting up the training environment to mastering advanced techniques, discover how the MC306 dome simulator is transforming valve leak training, ensuring your team is prepared for any challenge.”

- MC306 Hardware: A Dome Training Simulator

- Understanding Valve Leak Scenarios for Training

- Benefits of Using MC306 for Hands-On Practice

- Setting Up the MC306 Dome Training Environment

- Advanced Techniques with the MC306 Simulator

MC306 Hardware: A Dome Training Simulator

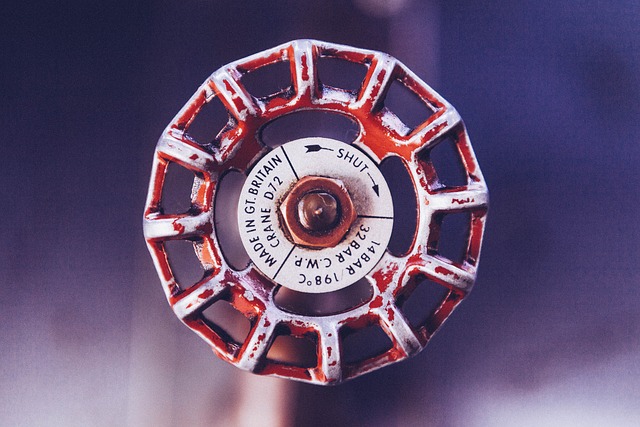

The MC306 Dome Training Simulator stands as a cutting-edge solution in valve leak training, offering a realistic and immersive learning environment for professionals in the industrial sector. This innovative hardware replicates complex valve systems within a controlled dome, enabling trainees to practice leak detection and repair skills without the risks associated with real-world scenarios.

The simulator’s design incorporates advanced technologies to create a dynamic and interactive experience. Trainees can manipulate valves, observe system responses, and simulate various leak conditions, all while receiving real-time feedback. This hands-on approach accelerates learning, enhances problem-solving abilities, and prepares individuals for high-pressure situations in their professional careers, making the MC306 Dome Training Simulator an indispensable tool for comprehensive valve leak training.

Understanding Valve Leak Scenarios for Training

Valve leak scenarios are critical components of any comprehensive training program for maintenance professionals, especially those working with MC306 dome training simulators. These simulations offer a safe and controlled environment to practice identifying and addressing valve leaks, which is crucial for preventing costly downtime and ensuring plant safety. By replicating various leak conditions, from subtle drips to full-blown emergencies, the MC306 dome training simulator prepares technicians to handle unexpected issues effectively.

Understanding different valve leak scenarios allows trainees to gain practical experience in a risk-free setting. They learn to recognize the signs of leaks, such as unusual noises, pressure drops, or visual indications on instruments. This knowledge equips them to take prompt action, whether it involves isolating the leaking valve, applying repair techniques, or mobilizing emergency response measures. The MC306 dome simulator’s versatility in simulating diverse leak scenarios makes it an indispensable tool for fostering skilled and confident maintenance personnel.

Benefits of Using MC306 for Hands-On Practice

The MC306 dome training simulator offers a unique and immersive learning experience for valve leak training, making it an invaluable tool for professionals in the field. Its primary benefit lies in providing a safe and controlled environment for practitioners to gain hands-on skills without the risks associated with real-world scenarios. This simulator recreates intricate valve systems and allows trainees to simulate various leak conditions, fostering a deep understanding of leak detection and repair procedures.

With its advanced technology, the MC306 offers realistic simulations, ensuring that learners can practice troubleshooting and fix leaks in a complex dome environment. This practical approach enhances their problem-solving abilities and prepares them for unexpected challenges on actual job sites. The use of this simulator not only reduces training costs but also contributes to improved safety standards, as trainees can master critical skills without endangering themselves or others.

Setting Up the MC306 Dome Training Environment

Setting up the MC306 Dome Training Environment is a crucial step in preparing for comprehensive valve leak training. This cutting-edge MC306 dome training simulator offers an immersive and realistic experience, replicating actual industrial conditions. By recreating the intricate details of a dome, from sensor placements to pressure dynamics, it provides a safe and controlled space for technicians to hone their skills.

The process involves carefully arranging the hardware components, including the MC306 controller and associated sensors, within the simulated environment. This setup allows trainees to interact with virtual valves, observe real-time data feeds, and respond to leak scenarios as they would in a live plant. With precise control over variables like pressure, temperature, and flow rates, instructors can tailor training sessions to different experience levels and specific plant requirements.

Advanced Techniques with the MC306 Simulator

The MC306 Dome Training Simulator takes valve leak training to a new level by incorporating advanced techniques that offer a comprehensive learning experience. This state-of-the-art tool simulates real-world conditions, allowing technicians to practice and perfect their skills in a controlled environment. With its intricate design, the simulator reproduces the complexities of industrial systems, ensuring users are well-prepared for any on-site challenges.

Through interactive scenarios and detailed feedback mechanisms, trainees can identify and address leaks efficiently. The MC306 provides an immersive experience, enabling them to navigate through intricate valve systems, diagnose issues, and implement effective repair strategies. This cutting-edge technology not only enhances learning but also promotes safer and more competent technician performance, making it a valuable asset for any maintenance team.